Key Aspects of Producing and Manufacturing Soft Goods

Manufacturing a garment or another new consumer product using soft goods is a highly-technical process that can be quite overwhelming if it’s something you’ve never done before.

Manufacturing a garment or another new consumer product using soft goods is a highly-technical process that can be quite overwhelming if it’s something you’ve never done before.

An avid outdoorsman, entrepreneur and former Royal Marine, Ranger has addressed a need for replenishable power outside of urban areas. Although recharging is often easy in our world of smartphones and battery-powered devices, with power outlets and charging stations readily available, it is a challenge in remote outdoor areas.

There are many different processes we use to make hard goods at Enventys Partners. Ultimately, it boils down to determining the most cost-effective way to produce your product. This is determined by several factors, including the budget for product development, the quantity of the item the client hopes to sell, and various design requirements.

Part of understanding how we make our products is understanding the types of materials we use. In this article we walk through a few of the options to give a better understanding of how we build products using technical soft goods.

One of my hobbies and great passions is gardening, so I was thrilled when Rhode Island software developer Suriyont (Suri) Mujjalintrakool brought his connected terrarium prototype to Enventys Partners.

Why should you outsource your product development? When you start examining the time, money and resources it will take to get it to market, the advantages will become obvious.

A crucial aspect of developing a new product is always determining the right sourcing solution for your needs. While the traditional option was to opt for a single source, dual sourcing has become more popular. To figure out if this makes sense for your particular product, explore the pros and cons of dual sourcing.

What can inventors of smart home products and home automation solutions learn from Nest’s social media smarts?

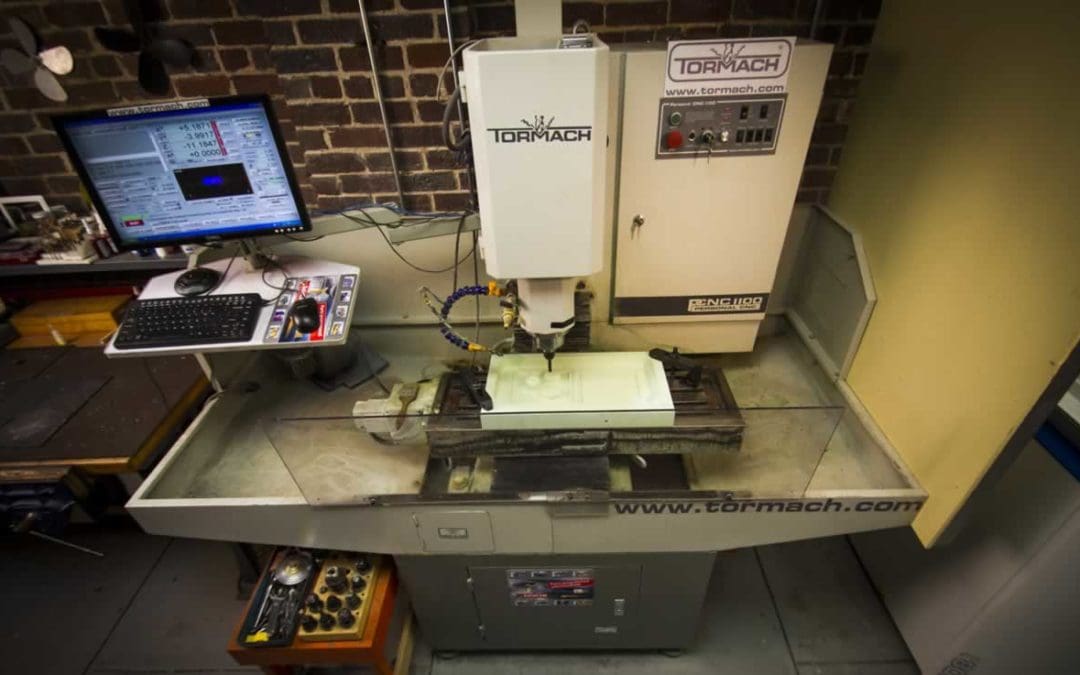

CNC, or computerized numerical control, is a method for machining of parts. The first CNC machines were developed in the 1940s and 1950s and worked from punched paper tapes.

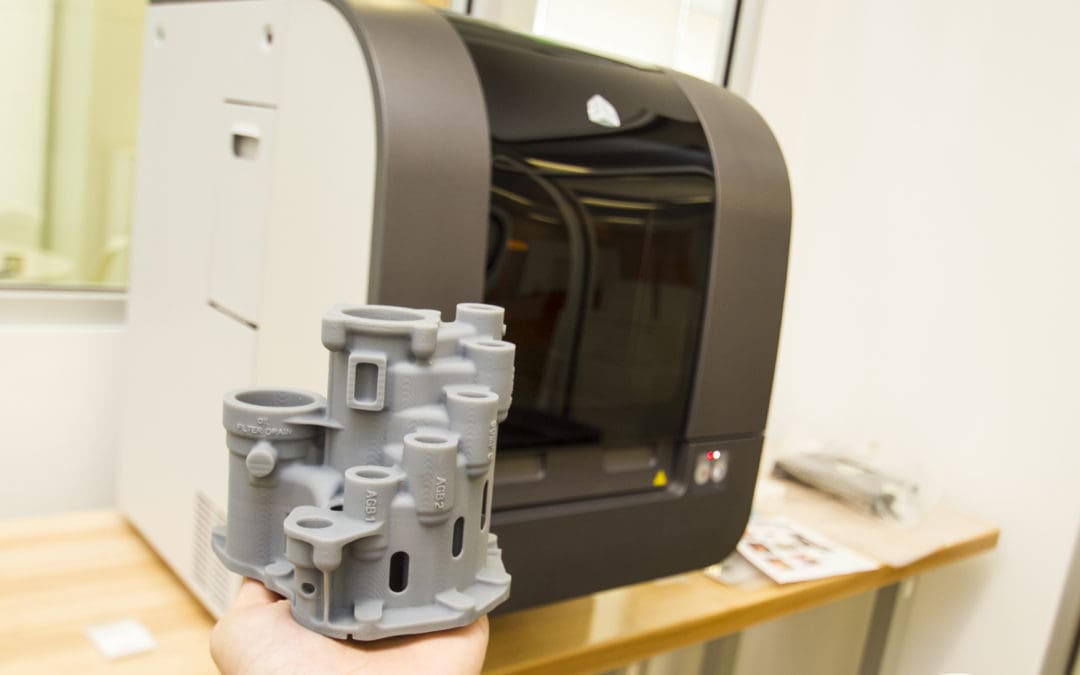

The development and improvement of 3D printing, or the additive process of building up an object layer by layer, turned a new page in manufacturing. The change came slowly at first but has accelerated over the past few years.